A career in the lighting industry, a passion for the environment and an unflagging entrepreneurial spirit is what drives SpecGrade LED CEO Rick Nathans, as he leads a team dedicated to making the best LED grow lights and other innovative products for horticulture.

“I have a vision to change the world,” Nathans said. “In this one area, I think I can do that.”

Nathans majored in accounting and finance at the University of Cincinnati and quickly discovered a career in either field wasn’t for him. So, he started working at a family-owned lighting business in Cleveland and discovered he liked it – but he wanted to work for himself. A move to Columbus allowed him to open his own lighting showroom and he sold residential lights, lamps and fixtures for nearly two decades. In 2008, the market on residential real estate collapsed and his business – heavily weighted in residential construction – floundered, ultimately closing in 2010.

He knew enough about lighting to see that the future was in LED lights, so he started building his own fixtures in his basement and started selling them throughout North America. The demand for LED lights – especially in the up-and-coming cannabis industry – was booming.

“The need for high-output, precision optics was there for the horticultural industry,” Nathans said. “And these were things I was good at.”

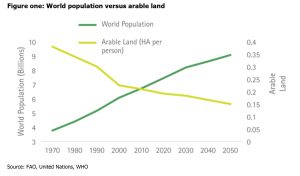

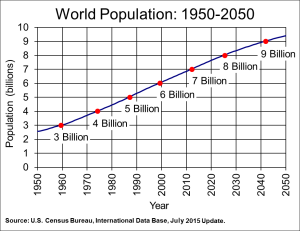

Nathans had long been interested in agriculture and the environment, especially how farmers were changing the farming industry due to overpopulation, changing climate and declining arable land. The writing was on the wall: Farming had to go indoors, and go vertical – and growers needed to throw out their old grow lighting technology and invest in LED lights to grow crops indoors.

“I’m not comparing myself to Steve Jobs but I identified with him when he said he felt like putting a ding into the universe. It was my calling to put a ding into the universe as well,” Nathans said. “I know we can’t continue to farm and feed the planet the way we are currently. It needs to change. And I want to be a part of that change. By 2050, this planet won’t be able to feed itself.”

Originally, grow lights being used in horticultural operations were the kind of lights used to illuminate sports stadiums or highways. They weren’t meant to grow plants, and they consume a large amount of electricity (and generate a lot of heat). That isn’t sustainable in an indoor growing operation – especially one that spans acres. That goes for food and cannabis, Nathans said.

LED grow lights cut the electricity used by about 40 percent and the lights last longer. They also use less harmful materials – making them better for the environment. And that sustainability is what is driving the next generation of SpecGrade LED products.

From the top down, SpecGrade has a commitment to sustainability. SpecGrade’s lights are different from the competition, in that they are modular – parts that wear out can be replaced (keeping more trash out of landfills) and they also use less electricity (which is less of a drain on the system).

SpecGrade LED under Nathans’ direction continues to innovate, and try to stay ahead of the competition, while maintaining the company’s “North Star” commitment to environmentally friendly practices.

Since his “aha moment” of realizing the horticultural industry needed a better-quality light that could withstand the rigorous challenges of an indoor growing operation – humidity, dust, heat and dirt – he and his team have worked to engineer lights built to stand the test of time.

“We took the approach of over-engineering our lights,” he said. “It has served us well.”

“Hardly anything we make ever fails,” he said. “We know what it takes to make a quality product. Our competitors think we are in the lighting business but we see it as being in the electronics business. That basically means, we use more aluminum to get better heat transfer. That means the light burns cooler. And in the electronics world, heat is a killer – meaning the cooler something is the longer it lasts.”

But in recent years, the competition is coming around to the SpecGrade LED way, so Nathans said the company is seeking to raise the bar even higher.

“We believe there is a better way to do things in the LED grow light industry,” he said. “For example, we’ve taken planned obsolescence out of the picture. There are better ways to build LED grow lights. You can build them not only to last longer, but you can build them so they can be repaired, replaced and ultimately recycled. As technology evolves, you can swap out parts, like the driver, to keep your lighting up to date.”

And with Controlled Environment Agriculture, or CEA, becoming more and more popular, the time is now to continue to innovate. CEA is, at its essence, a technology-based approach to farming. Meaning as it gains popularity, farmers and those in the horticultural industry, will be more open and ready to embrace technology.

SpecGrade LED is up to the challenge and is actively ramping up to lead in that direction. CEA means growers are effectively creating an entire ecosystem in a warehouse, greenhouse, container – there are a number of options. And in that ecosystem, there is a need for monitoring and controlling factors and variables like water, lighting, HVAC, nutrients.the next innovation for SpecGrade LED is a system that allows growers to do that on a tablet, phone or computer with its Grow Connect Controls system set to launch this year.

“This is the future of indoor agriculture,” Nathans said. “If you are growing more than a few plants, you need this level of control to monitor it from a distance.

“We are positioning ourselves to be an industry leader. We’re ready.”